Hydraulic Hose DIN EN857 1SC More flexible

Construction:

Tube: Oil resistant synthetic rubber

Reinforcement: One braid of high tensile steel wire.

Cover: Black, abrasion and weather resistant synthetic rubber, MSHA accepted.

Temperature: -40℃ to +100 ℃

EN857-1SC Hydraulic Hose with One Layer of Steel Wire Reinforcement

EN857-1SC hydraulic hose is suitable for petroleum-based hydraulic oil delivering. It is composed of three parts: tube, reinforcement and cover. Tube is made from oil resistant synthetic rubber, making hose perform well in delivering hydraulic oil. Reinforcement is made from one layer of high tensile steel wire, making hose have solid structure and bear high working pressure. Cover is made from oil and weather resistant synthetic rubber, making hose resistant to corrosion, abrasion and aging. So the hose can be used in harsh working environment.

The details of EN857-1SC hydraulic hose:

Structure: it is composed of three parts: tube, reinforcement and cover.

Tube: oil resistant synthetic rubber.

Reinforcement: one layer of high tensile steel wire.

Cover: oil and weather resistant synthetic rubber.

Temperature range: -40 °C to +100 °C.

EN 857 1SC single wire braid hydraulic hose for tight routing

Reinforced by one high tensile wire braid, EN 857 1SC hydraulic hose has similar performance as its counterpart SAE 100R1 besides tighter bending radii. Ozone and weather resistant cover separate the tube from the outside environment and effectively extend the service life of hose. Single wire braided 1SC high pressure hydraulic hose is suitable for high pressure conditions where tight routing is required.

Product description:

EN 857 1SC hydraulic rubber hose

EN 857 1SC Hose

Tube: Oil resistant synthetic rubber;

Cover: abrasion and ozone resistant synthetic rubber;

Reinforcement: one braid of high tensile wire;

Max working pressure: 3260psi (22.5Mpa);

Working temperature: -40 to 100°C (-40 to 212°F);

Min bend radius: 75mm;

Inside diameter: 1/4" to 1";

Safety factor: 4:1;

Pressure grade: high.

Specification:

| Part No. | I.D. | O.D. | W.P | B.P | B.R | W.T | |||

| Dash | Inch | mm | mm | MPa | PSI | MPa | PSI | mm | kg/m |

| 1SC-04 | 1/4″ | 6.4 | 13.5 | 22.5 | 3263 | 90 | 13050 | 75 | 0.173 |

| 1SC-05 | 5/16″ | 7.9 | 14.5 | 21.5 | 3118 | 85 | 12325 | 85 | 0.194 |

| 1SC-06 | 3/8″ | 9.5 | 16.9 | 18.0 | 2610 | 72 | 10440 | 90 | 0.244 |

| 1SC-08 | 1/2″ | 12.7 | 20.4 | 16.0 | 2320 | 64 | 9280 | 130 | 0.328 |

| 1SC-10 | 5/8″ | 15.9 | 23.0 | 13.0 | 1885 | 52 | 7540 | 150 | 0.416 |

| 1SC-12 | 3/4″ | 19.1 | 26.7 | 10.5 | 1523 | 42 | 6090 | 180 | 0.500 |

| 1SC-16 | 1″ | 25.4 | 34.9 | 8.7 | 1262 | 35.2 | 5075 | 230 | 0.713 |

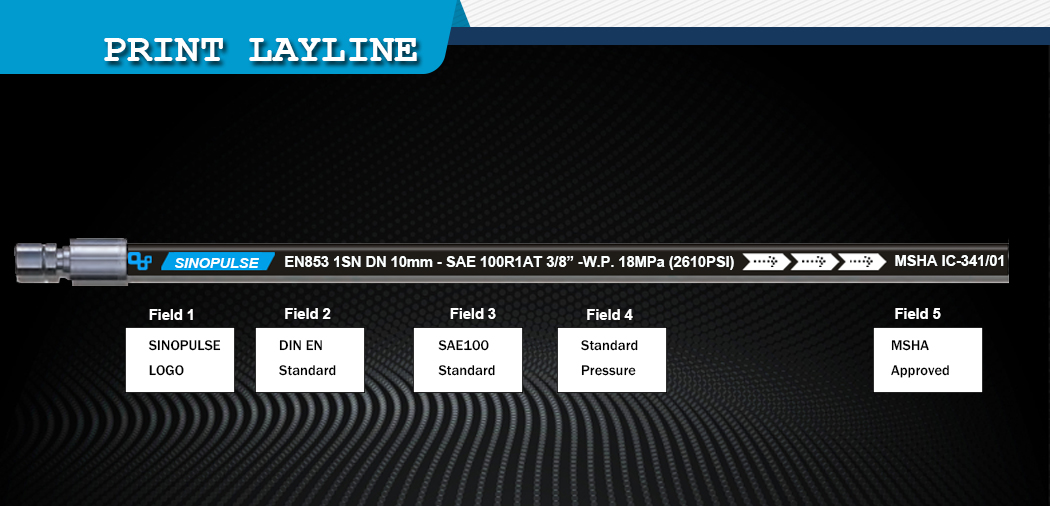

Let me analyse why choose us:

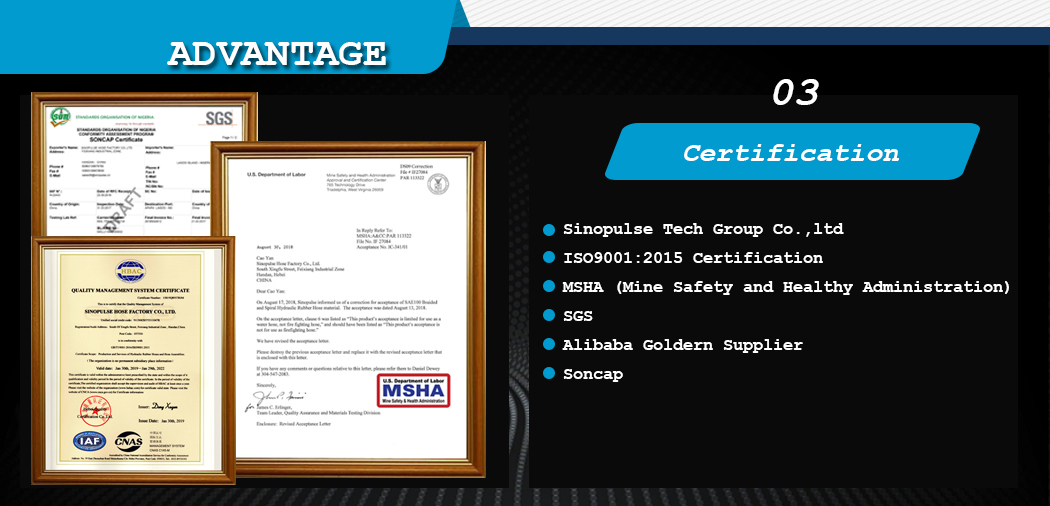

Our company is the long term ISO9001: 2015 Certification manufacturer and exporter for full range Hydraulic hose, Industrial Hoses, PVC hose pipe, Pneumatic tubes.

Our products passed the MSHA no. IC-341/01. We are the trust worthy manufacturer, which are professional and reliable supplier

Our hoses passed the Gost certification this year, and we have done the cold weather testing of the hose up to -40℃.

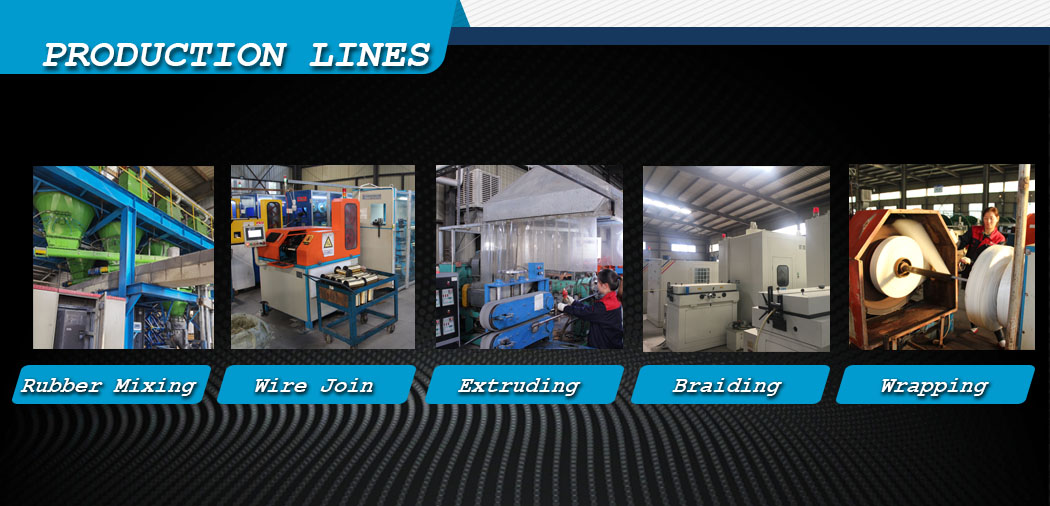

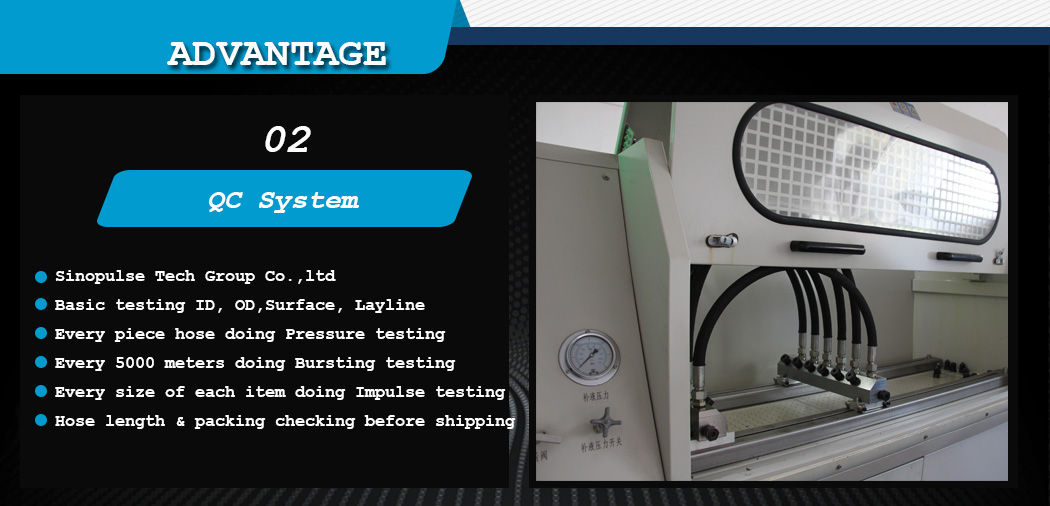

The most important reason to choose us is what the test we are doing everyday of the products before, during and after production.

For example, before the production, we have done various kinds of test for the rubber material , like the rubber strength, rubber hardness, rubber vulcanization, adhesive, aging, ozone, cold weather. And the testing for the steel wire strength.

During the production, we have the Identity card to show the production progress, who will responsible for the each production chain.

After the production, we need to testing the proof pressure 2 times than the working pressure every roll of hoses, and test the bursting pressure 4 times than the working pressure.

We have done the impulse test to show the products working life, It should be noted that our products are fully compliant with DIN EN 857 1SC

We have a large hydraulic hose range in the market, which can be satisfied with your different pressure application.

SAE100 R1AT/EN 853 1SN (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R2AT/EN853 2SN (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

DIN 20023/EN 856 4SP (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

DIN 20023/EN 856 4SH (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R12 (FOUR STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R13 (FOUR OR SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

SAE100 R15 (SIX STEEL WIRE SPIRAL HYDRAULIC HOSE)

EN 857 1SC (ONE STEEL WIRE BRAIDED HYDRAULIC HOSE)

EN857 2SC (TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R16 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R17 (ONE OR TWO STEEL WIRE BRAIDED HYDRAULIC HOSE)

SAE100 R3 / EN 854 2TE (TWO FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R6 / EN 854 1TE (ONE FIBRE BRAIDED HYDRAULIC HOSE)

SAE100 R5 (FIBER BRAIDED COVER HYDRAULIC HOSE)

SAE100 R4 (HYDRAULIC OIL SUCTION HOSE)

SAE100 R14 (PTFE SS304 BRAIDED)

SAE100 R7 (ONE WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

SAE100 R8 (TWO WIRE OR FIBRE BRAIDED THERMOPLASTIC HOSE)

Talk With our Team:

Skype: sinopulse.carrie

WhatsApp: +86-15803319351

Wechat: +86+15803319351

Mobile: +86-15803319351

Email: carrie@sinopulse.cn

Add: South of xingfu road, Feixiang Industrial Zone, Handan, Hebei, China

Write your message here and send it to us